You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

NG Models 747-8

- Thread starter pons399

- Start date

OscarBravo992

Well-known member

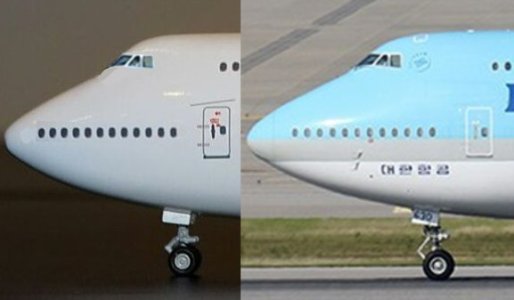

So a "sad" 747?Upon closer inspection the center windows are too large, and the whole thing's slanted downwards instead of being straight. Basically the opposite of JC's issue with "angry" 747s.

pons399

Well-known member

PreciselySo a "sad" 747?Either way, this is a bloody good mould, and we should consider ourselves lucky to have it. Hopefully these 'bumps in the road' get ironed out before the first release hits the shelves.

1. Smaller, straighter cockpit windows

2. Fan blades with correct orientation

3. Straighter windowline at the front that's slightly farther back

4. Cleaned-up APU

Overall i'm very pleased with the result, but I think the "forehead" (that area above the cockpit window) needs to be more smooth. More curved.

Don’t forget how they nailed the L-1011. They got everything right - right down to the ‘dolphin’ nose. Lots of the difficult nuances that no manufacturer had mastered until this mould. Importantly, this had all been achieved at the sample stage! They should be nailing the 747 in the same way, but they haven’t been - so yes, I hope they iron these things out, as otherwise it won’t be definitive like the L-1011 is, which would be a shame, especially as so many are clamouring for the classics to be done.So a "sad" 747?Either way, this is a bloody good mould, and we should consider ourselves lucky to have it. Hopefully these 'bumps in the road' get ironed out before the first release hits the shelves.

Phantom

Well-known member

I wish they'd "deliver" those samples without any printing as it only detracts from the shape. Some flat grey coating instead of gloss could help as well.

Still curious to see te -8F. With what I saw that far I'm not positive.

The -8I certainly needs some tweaks to the nose: radome to cockpit profile is too "straight" and the cockpit area a bit squared looking.

Nitpicky, yes. But this is NG.

Still curious to see te -8F. With what I saw that far I'm not positive.

The -8I certainly needs some tweaks to the nose: radome to cockpit profile is too "straight" and the cockpit area a bit squared looking.

Nitpicky, yes. But this is NG.

The thing that worries me is, this is a very late stage for any physical revisions to made on the tooling - the very expensive process of producing the moulds has been completed, now that samples have been shown means it’s ready for production. I don’t see how corrections like this can be made; I assume the moulds themselves are CNC machined? If some refinements required material to be removed, I can see how this could be done; extra machining/milling operations; but if additional material needs to be added to refine a shape/profile; what then? All this would be extremely expensive to execute at this late stage. Printing alterations are very easy to resolve however.

pons399

Well-known member

Upon close inspection the whole frontal area has lots of room for improvement.

1. Cockpit windows are too tall vertically and too short horizontally.

2. The cockpit-hump transition should be a bit more streamlined; currently it's too angular.

3. Windowline ahead of the L1/R1 doors should be straightened.

4. Just as a note, the number of windows in front of the L1/R1 doors differs by airline. Lufthansa has 14, Korean and Air China have 12.

Most of the issues are easily remediable, as they're printing-related. I'll probably email NG with some suggestions.

1. Cockpit windows are too tall vertically and too short horizontally.

2. The cockpit-hump transition should be a bit more streamlined; currently it's too angular.

3. Windowline ahead of the L1/R1 doors should be straightened.

4. Just as a note, the number of windows in front of the L1/R1 doors differs by airline. Lufthansa has 14, Korean and Air China have 12.

Most of the issues are easily remediable, as they're printing-related. I'll probably email NG with some suggestions.

Last edited:

Upon close inspection the whole frontal area has lots of room for improvement.

1. Cockpit windows are too tall vertically and too short horizontally.

2. The cockpit-hump transition should be a bit more streamlined; currently it's too angular.

3. Windowline ahead of the L1/R1 doors should be straightened.

4. Just as a note, the number of windows in front of the L1/R1 doors differs by airline. Lufthansa has 14, Korean and Air China have 12.

Most of the issues are easily remediable, as they're printing-related. I'll probably email NG with some suggestions.

Fully agree with all these!

pons399

Well-known member

The "forehead" issue could probably be resolved by shaving off some material and making the cockpit-hump transition smoother, so it's definitely within the realm of possibility.The thing that worries me is, this is a very late stage for any physical revisions to made on the tooling - the very expensive process of producing the moulds has been completed, now that samples have been shown means it’s ready for production. I don’t see how corrections like this can be made; I assume the moulds themselves are CNC machined? If some refinements required material to be removed, I can see how this could be done; extra machining/milling operations; but if additional material needs to be added to refine a shape/profile; what then? All this would be extremely expensive to execute at this late stage. Printing alterations are very easy to resolve however.

Phantom

Well-known member

Don't forget that shaving off material from a cast means adding material to the mould.The "forehead" issue could probably be resolved by shaving off some material and making the cockpit-hump transition smoother, so it's definitely within the realm of possibility.

pons399

Well-known member

Right, my bad. Guess we shouldn't expect that particular issue to be fixed, at least on the first release. The printing and fan blades are inexcusable if left unaltered, though.Don't forget that shaving off material from a cast means adding material to the mould.

Totally agree with youUpon close inspection the whole frontal area has lots of room for improvement.

View attachment 13874

1. Cockpit windows are too tall vertically and too short horizontally.

2. The cockpit-hump transition should be a bit more streamlined; currently it's too angular.

3. Windowline ahead of the L1/R1 doors should be straightened.

4. Just as a note, the number of windows in front of the L1/R1 doors differs by airline. Lufthansa has 14, Korean and Air China have 12.

Most of the issues are easily remediable, as they're printing-related. I'll probably email NG with some suggestions.

Yes, it’s all in reverseDon't forget that shaving off material from a cast means adding material to the mould.

I remember one mould appeared years and years ago for a 747-300/400 which had been badly converted from a -100/200 mould. A poor job was made - the additional area of the upper-deck had been machined out but it failed to meet the level path at the right point before the original slope began, leaving a ‘dent’ impression in the hump. It looked terrible!

Phantom

Well-known member

I spent a few years working (training) in the "mould business", though our moulds were used for precission casts of tech ceramics. Naturally die sinking EDM was the way to go and electrodes were done using precission milling in a CAM environment. This was last century!Yes, it’s all in reverse… So, the tweak in this case would require material to be added in the mould which would be extremely difficult to do - I’m not even sure this can be done? If so I’d love to know the method. +/- changes at this scale would be minute.

I remember one mould appeared years and years ago for a 747-300/400 which had been badly converted from a -100/200 mould. A poor job was made - the additional area of the upper-deck had been machined out but it failed to meet the level path at the right point before the original slope began, leaving a ‘dent’ impression in the hump. It looked terrible!

But that raises my question: HOW can shapes of diecast models be off? Aren't they based on CAD (so that shapes can be triple checked via render or 3D-printing before producing the mould) but really old old school "hand carved"?

I thought NG is a bit more "Next Generation" here.

Depending on the mould you could weld on material and then work it to shape. Not sure in how far this is doable in this case.

Last edited:

That’s really interesting, thanks for that insightI spent a few years working (training) in the "mould business", though our moulds were used for precission casts of tech ceramics. Naturally die sinking EDM was the way to go and electrodes were done using precission milling in a CAM environment. This was last century!

But that raises my question: HOW can shapes of diecast models be off? Aren't they based on CAD (so that shapes can be triple checked via render or 3D-printing before producing the mould) but really old old school "hand carved"?

That is a really good question you raise - and one which I ask myself, because the issue of mould accuracy affects all scale models in various hobbies, and discussions such as this are taking place right now in 00/HO railway modelling. Tools such as 3D laser scanning have advanced and aided accuracy in CAD/CAM, with access to the prototype - site visits are conducted to carry out surveys to support the work. However this is with preserved railway organisations within the UK, and info is then sent to the factory in China from UK-based companies. It must simply be down to access to enough raw information? I know NG were given actual blueprint data for the L-1011 - this resulted in a highly accurate tooling. Perhaps the same level of info has not been available in the instance of the 747?

Phantom

Well-known member

I know NG were given actual blueprint data for the L-1011 - this resulted in a highly accurate tooling. Perhaps the same level of info has not been available in the instance of the 747?

Sounds like a good explanation as their TriStar (and maybe Panda's 134) are among the very few "flawless" looking castings.

Similar threads

- Replies

- 0

- Views

- 345

- Replies

- 0

- Views

- 96