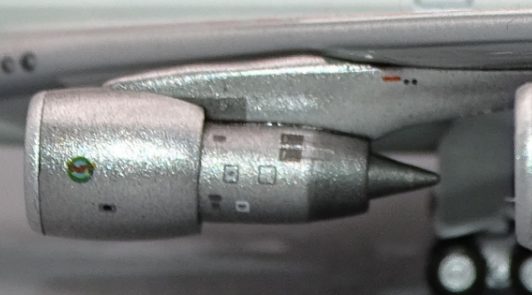

Yes this isn't an operational 747 I agree but as a 400 times smaller replica I think you're being harsh. The wing thickness comes down to having a model that doesn't have wings that snap off when you touch it. I don't see anything wrong with the pylon shape and the inlet ring is poorly fitted on that particular example. It is an extra piece to allow the fan detailing. Once again, to get a model 400 times smaller you can't make a 100% replica - compromises are required. The image below is from the HX prototype. You'll notice the inlet ring is fitted better.

I maintain the accuracy you are looking for isn't achievable at the price bracket you want or without risking QC issues that make the model hard to ship. To my eye this is a near perfect engine pylon set for a 400 scale 747.

You're all going to be waiting an eternity for a better 747 in 400 scale because the NG's engines / pylons don't match this, even if they modify them.

View attachment 47671

Richard, I understand that the technical/engineering part of the hobby isn't your speciality.

There's a lot that can be done and plenty of moulds showcase this. The question is what the manufacturer is trying to achive with a given budget (scale accuracy or "gimmicks") and I observe that HX goes a different way than what Panda or NG usually go.

For sure HX wont do a new wing. NOT because the wings would snap (come on ?!) when they are realistically thick - they aren't far from it and only have an incorrect airfoil - but because benefits are in absolutely no relation to effort. We all agree, but hey, this is a discussion forum, isn't it?

The pylons could be adjusted to fit the given wing profile by just altering the LE and the contact line to the wing. A retool that only depends on whether HX are content with what they have or not. But a problem for neither engineering nor quality.

Thinking about the engine I'd have half a dozen different approaches in mind of how to design a 400 scale JT9D. HX opted for the more complex approach which sadly doesn't yield the highest accuracy, but follows the recent trend of having more gimmicks. Hollow core with 16 fan blades to "see through"! Too bad the real thing barely allows any see through with its 46 (!) blades. So instead of adding all this complexity and possible QC issues with that inlet ring and see through fan, they could have easily gone the simple appraoch with a solid core fan and a single piece fan cowl. While maybe not achieving a proper count of 46, it would have led to a noticably increased scale accuracy around the inlet, likely less costs and less QC concerns. Ironically, the fan cowl dimension on HX looks fairly good without the inlet ring.

I back you up on this. I think many of us need to understand that these models are very labor-intensive. Combine that with the fact that they are relatively in low demand, and it becomes evident that these models should cost more, but the industry is largely kept alive by a bunch of aviation nuts who, to some extent, subsidize it.

Also, there are as many of us collectors complaining for more accuracy as there are those who complain about poor QC. Some are even on both bands. Guys, I have been hinting at it for a while: These models don't travel well. The more detail and accuracy you get come at the expense of more pieces scattered around the cradle when you receive the model.

I don't see anyone demanding anything that would pose an additonal risk for QC or transport safety. Au contraire. Three of the four points listed would actually improve both. And while I agree that a new wing is unfeasible it also wouldn't change anything to the worse here.

And just to repeat it one more time:

HX currently offers the best 747 on the market, yes, but it is not as great as some of us have hoped for a new 747Classic mould. Blame NG or Panda for raising the bar that high.

www.facebook.com

www.facebook.com

www.facebook.com

www.facebook.com