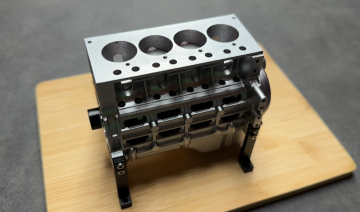

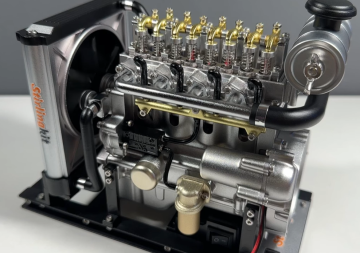

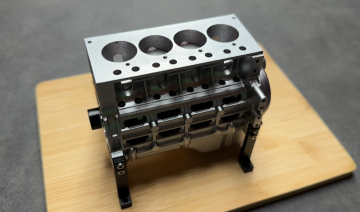

Just wanted to share my progress on the Teching OHV 4-cylinder mini diesel engine kit. I’ve finished the main assembly of the model — the block, pistons, crankshaft, and camshaft are all in place now. It’s been an awesome build so far!

The precision of the metal parts and the working mechanism really make it feel like a tiny, real engine. I’m amazed how smoothly the pistons move when I turn the crank.

Here are some pics of the current build (see attachments). I still have some smaller details and final touches to add, but the core is all together.

Has anyone else built this kit or something similar? Would love to hear your tips or experiences! Also open to suggestions on what to tackle next.

Thanks for checking it out!

The precision of the metal parts and the working mechanism really make it feel like a tiny, real engine. I’m amazed how smoothly the pistons move when I turn the crank.

Here are some pics of the current build (see attachments). I still have some smaller details and final touches to add, but the core is all together.

Has anyone else built this kit or something similar? Would love to hear your tips or experiences! Also open to suggestions on what to tackle next.

Thanks for checking it out!